Four advantages

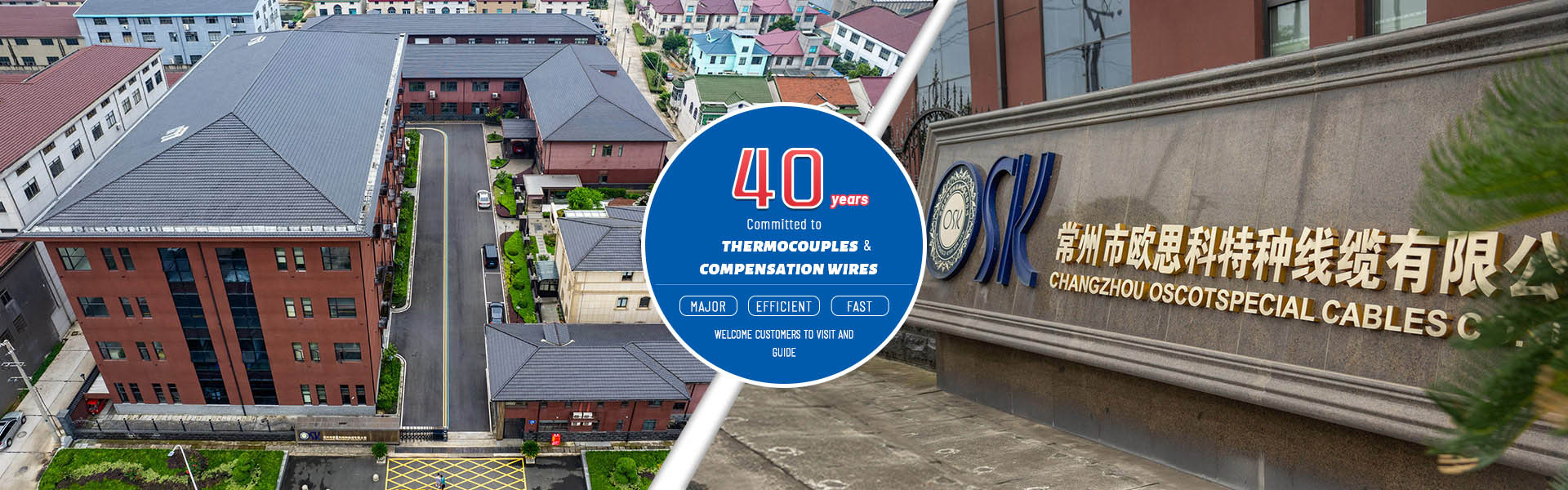

40 YEARS OF EXPERIENCE IN THERMOCOUPLE PRODUCTION AND DEVELOPMENT

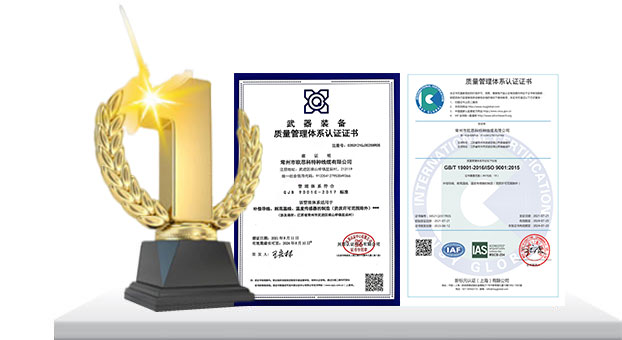

INTERNATIONAL STANDARDS, QUALITY IS GUARANTEED

NON-STANDARD PERSONALITY CUSTOMIZATION

QUALITY SERVICES, CLOSE TO REST ASSURED

OSK special cable - Customization process

Integrate advanced technology and concepts to keep up with the international trend. We have cooperated with many domestic enterprises for many years and established a good reputation. Consult

Consult Analyze

Analyze Plan

Plan Discussion

Discussion Production

Production Debug

Debug Ship

Ship

ABOUT OSK - Quality makes brand

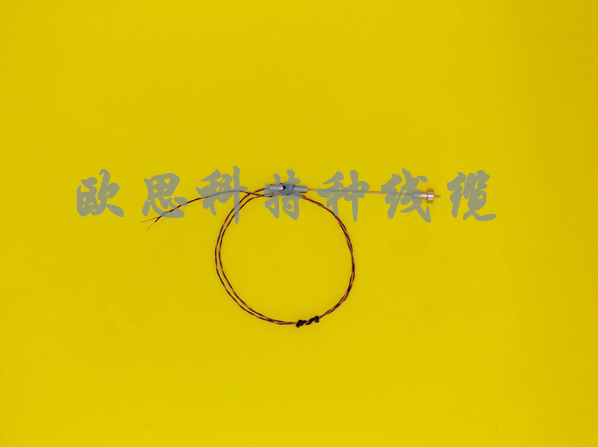

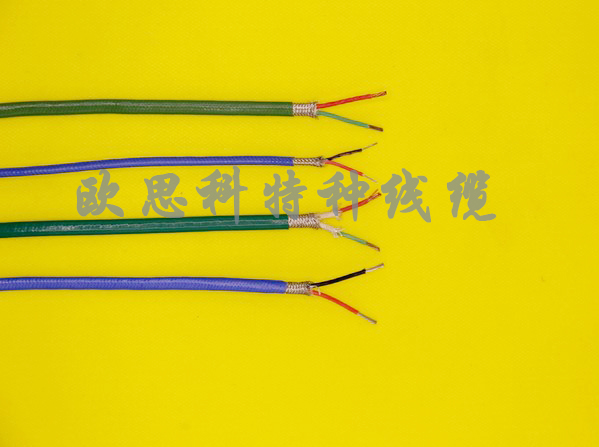

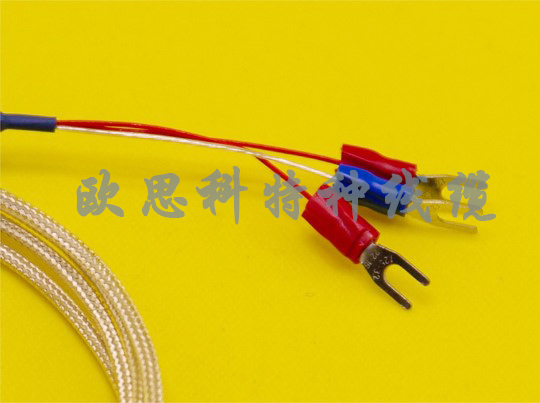

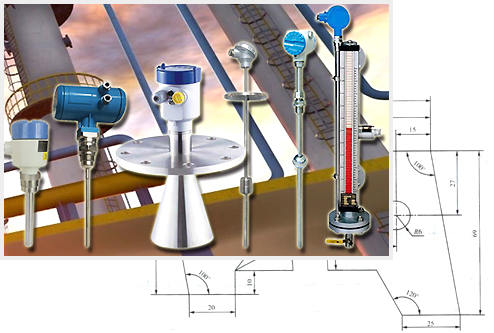

Main business Thermocouple Thermal resistance Compensation wire

More than 40 years ago, akin to sowing seeds in fertile soil, we initiated the establishment of this factory. Over time, that seed has germinated into a towering tree, mirroring our steadfast commitment to the thermocouple industry. With integrity and professionalism as our guiding principles, we strive to provide exceptional products and services to our clientele. Our factory boasts certifications in ISO 9001, ISO 14001, and ISO 45001, emblematic of our dedication and exemplary performance in quality management, environmental stewardship, and occupational health and safety.Our product portfolio encompasses a wide array of offerings, including temperature-compensated thermocouples, (micro) armored thermocouples, platinum resistance thermometers, electric heaters, armored thermocouple cables, intelligent temperature (PID) controllers, and noble metal compensating wires such as nickel-chromium-iron. Each product is meticulously crafted, embodying advanced craftsmanship and precision engineeringFueled by passion and innovation, our team is committed to delivering cutting-edge solutions to our clientele. Whether catering to the demanding conditions of high-temperature steel mills or the extreme cold of polar facilities, our thermocouples serve as steadfast sentinels, safeguarding production processes' stability and safety.Central to our ethos is a customer-centric approach. We prioritize personalized service, tailored to meet each client's unique requirements and expectations. Our enthusiastic customer service team stands ready to provide comprehensive support and assistance, underscoring our unwavering dedication to customer satisfaction.Through relentless pursuit of excellence and a culture of continual innovation, we are poised to collaboratively forge a dynamic and prosperous future with our partners and stakeholders.Hotline: +8613806110632

-

Our Environmental Commitment

Our Environmental CommitmentOn this beautiful blue planet, we deeply understand that each of us has a responsibility to protect and cherish our environment. As a company dedicated to creating and providing high-quality thermocouple products, we firmly believe that environmental awareness is not only a responsibility but also an inevitable choice for our survival and development. Therefore, we solemnly pledge:1. Protecting the Earth from the Source: We will strive to reduce environmental burdens, starting from product design and material selection, prioritizing renewable and recyclable materials, and minimizing waste and resource wastage.2. Conserving Energy, Creating a Clean Future: We will actively promote energy conservation and emission reduction, adopt advanced production technologies and equipment, optimize production processes, reduce energy consumption and carbon emissions, and contribute to creating a clean and sustainable future.3. Lean Management, Pursuing Excellence: We will continuously improve and optimize the environmental management system, establish a sound internal audit and monitoring mechanism, ensure the comprehensive implementation and continuous improvement of environmental policies, and pursue excellence in environmental performance.4. All Employees Participating, Acting Together: We will encourage all employees to actively participate in environmental actions, raise environmental awareness, cultivate environmental habits, jointly protect our homeland, and contribute to a better tomorrow.5. Continuous Improvement, Constant Innovation: We will actively advocate innovation, continuously research and develop and promote environmentally friendly technologies and products, provide customers with more environmentally friendly and sustainable solutions, and promote the development and progress of the environmental protection industry.We believe that every small environmental action will converge into the ocean, and every environmental commitment will propel us towards a better future. Let us join hands, work together, and leave a more beautiful and prosperous Earth for our future generations!All Employees of a Thermocouple Manufacturing Company

Our Environmental CommitmentOn this beautiful blue planet, we deeply understand that each of us has a responsibility to protect and cherish our environment. As a company dedicated to creating and providing high-quality thermocouple products, we firmly believe that environmental awareness is not only a responsibility but also an inevitable choice for our survival and development. Therefore, we solemnly pledge:1. Protecting the Earth from the Source: We will strive to reduce environmental burdens, starting from product design and material selection, prioritizing renewable and recyclable materials, and minimizing waste and resource wastage.2. Conserving Energy, Creating a Clean Future: We will actively promote energy conservation and emission reduction, adopt advanced production technologies and equipment, optimize production processes, reduce energy consumption and carbon emissions, and contribute to creating a clean and sustainable future.3. Lean Management, Pursuing Excellence: We will continuously improve and optimize the environmental management system, establish a sound internal audit and monitoring mechanism, ensure the comprehensive implementation and continuous improvement of environmental policies, and pursue excellence in environmental performance.4. All Employees Participating, Acting Together: We will encourage all employees to actively participate in environmental actions, raise environmental awareness, cultivate environmental habits, jointly protect our homeland, and contribute to a better tomorrow.5. Continuous Improvement, Constant Innovation: We will actively advocate innovation, continuously research and develop and promote environmentally friendly technologies and products, provide customers with more environmentally friendly and sustainable solutions, and promote the development and progress of the environmental protection industry.We believe that every small environmental action will converge into the ocean, and every environmental commitment will propel us towards a better future. Let us join hands, work together, and leave a more beautiful and prosperous Earth for our future generations!All Employees of a Thermocouple Manufacturing Company

-

What is a thermocouple? What is the principle of a thermocouple?

A thermocouple refers to a type of temperature sensor utilized extensively in scientific and industrial settings for temperature measurement. The fundamental operating principle of a thermocouple relies on the thermoelectric effect. Typically constructed from two dissimilar metal wires, a thermocouple features a hot junction formed by their convergence and a cold junction connected to a temperature-measuring instrument. When subjected to varying temperatures, the hot junction generates a voltage differential between the two metal wires. This voltage difference, termed thermoelectric voltage, is directly proportional to the temperature gradient across the junction. Through meticulous measurement and analysis of this voltage, the temperature at the hot junction can be accurately determined. Renowned for their robustness, versatility, and broad temperature measurement range, thermocouples find wide-ranging applications across scientific research, industrial processes, and engineering domains.(From The Engineering Mindset)When discussing thermocouples, we are essentially delving into an instrument designed for temperature measurement in environments of extreme conditions. Envision yourself within a manufacturing facility's workshop, engulfed by roaring furnaces and machinery emanating intense heat. In such a setting, a dependable means of temperature measurement becomes imperative, and herein lies the role of thermocouples.The underlying principle of thermocouples is elegantly straightforward. They comprise two dissimilar metal wires, bonded or compressed to form a junction, termed the "hot end." The opposite end connects to a measuring apparatus, known as the "cold end." Exposure of the hot end to elevated temperatures induces a subtle electrical potential disparity between the metal wires. This potential discrepancy fluctuates in tandem with temperature alterations, akin to a mirror reflecting the environmental temperature dynamics.This generation of potential disparity is rooted in the thermoelectric effect, whereby the junction of two dissimilar metals produces a voltage difference in response to temperature differentials—a phenomenon commonly referred to as the Seebeck effect. Electrons within the metals perpetually migrate as temperatures ascend or descend, engendering the potential difference. Upon transmission to the measuring apparatus, this potential disparity undergoes interpretation and analysis. By quantifying its magnitude, the measuring apparatus accurately deduces the temperature at the hot end.Consequently, thermocouples transcend mere temperature-measuring tools, embodying sentinels capable of operating within extreme environments, perpetually safeguarding the stability and security of industrial processes.

A thermocouple refers to a type of temperature sensor utilized extensively in scientific and industrial settings for temperature measurement. The fundamental operating principle of a thermocouple relies on the thermoelectric effect. Typically constructed from two dissimilar metal wires, a thermocouple features a hot junction formed by their convergence and a cold junction connected to a temperature-measuring instrument. When subjected to varying temperatures, the hot junction generates a voltage differential between the two metal wires. This voltage difference, termed thermoelectric voltage, is directly proportional to the temperature gradient across the junction. Through meticulous measurement and analysis of this voltage, the temperature at the hot junction can be accurately determined. Renowned for their robustness, versatility, and broad temperature measurement range, thermocouples find wide-ranging applications across scientific research, industrial processes, and engineering domains.(From The Engineering Mindset)When discussing thermocouples, we are essentially delving into an instrument designed for temperature measurement in environments of extreme conditions. Envision yourself within a manufacturing facility's workshop, engulfed by roaring furnaces and machinery emanating intense heat. In such a setting, a dependable means of temperature measurement becomes imperative, and herein lies the role of thermocouples.The underlying principle of thermocouples is elegantly straightforward. They comprise two dissimilar metal wires, bonded or compressed to form a junction, termed the "hot end." The opposite end connects to a measuring apparatus, known as the "cold end." Exposure of the hot end to elevated temperatures induces a subtle electrical potential disparity between the metal wires. This potential discrepancy fluctuates in tandem with temperature alterations, akin to a mirror reflecting the environmental temperature dynamics.This generation of potential disparity is rooted in the thermoelectric effect, whereby the junction of two dissimilar metals produces a voltage difference in response to temperature differentials—a phenomenon commonly referred to as the Seebeck effect. Electrons within the metals perpetually migrate as temperatures ascend or descend, engendering the potential difference. Upon transmission to the measuring apparatus, this potential disparity undergoes interpretation and analysis. By quantifying its magnitude, the measuring apparatus accurately deduces the temperature at the hot end.Consequently, thermocouples transcend mere temperature-measuring tools, embodying sentinels capable of operating within extreme environments, perpetually safeguarding the stability and security of industrial processes.

-

What are the application areas of thermocouples?What are the common application scenarios?

Industrial Automation: Thermocouples are widely used in industrial control systems to monitor and regulate the temperature of various equipment and processes. For instance, they are employed to monitor furnace temperature, melting temperature, and heating system temperature. In the manufacturing industry, thermocouples are utilized to monitor and control temperatures in various production processes such as metalworking, plastic molding, and glass production.Energy Industry: In the production and transmission of energy, thermocouples are commonly used to monitor the temperature of equipment such as boilers, generators, and transmission lines, ensuring the safe operation and quality of products. In the petroleum and natural gas industry, thermocouples are used to monitor the temperature during the extraction, storage, and processing of oil and gas.Automotive Industry: In automobile manufacturing and maintenance, thermocouples are extensively employed to monitor the temperature of engines, transmission systems, exhaust systems, etc., ensuring the normal operation of engines and other critical components. In automotive electronic systems, thermocouples are also used to monitor the heat dissipation of electronic devices, preventing overheating and damage to electronic components.Healthcare: In medical equipment, thermocouples are used in devices such as thermometers and surgical instruments to accurately measure patients' body temperature, aiding healthcare professionals in diagnosis and treatment.Environmental Monitoring: Thermocouples are utilized to monitor temperature changes in the natural environment, such as in weather stations and greenhouses. In environmental protection and pollution monitoring, thermocouples are also widely applied to monitor temperature changes in the atmosphere, water bodies, and other environments.Food Processing and Storage: In the food processing industry, thermocouples are used to monitor temperatures in ovens, refrigeration equipment, etc., ensuring the safe production and storage of food.Aerospace: In the aerospace field, thermocouples are employed to monitor the temperature of aerospace components and devices, ensuring the safe operation of these components in extreme environments.Laboratory Research: In scientific research and laboratory settings, thermocouples are used for temperature monitoring in various experimental equipment and reaction vessels. They find applications in experiments across fields such as chemistry, physics, biology, etc.Chemical Engineering: In chemical production, thermocouples are used to monitor the temperature of equipment such as reaction vessels, distillation towers, and furnaces, ensuring that chemical reactions can proceed under suitable temperature conditions.Metallurgical Industry: In the steel production process, thermocouples are used to monitor temperatures in blast furnaces, smelting furnaces, etc., ensuring the smooth progress of production. In the production of metal alloys, thermocouples are used to monitor the melting point and melting state of alloys, controlling the composition and quality of alloys.Power Industry: In power equipment, thermocouples are used to monitor the temperature of equipment such as transformers, cables, and generators, ensuring the stable operation of power systems.Textile Industry: In textile production, thermocouples are used to monitor temperatures in spinning machines, drying machines, etc., ensuring the quality and production efficiency of fibers.Ocean Engineering: In marine environments, thermocouples are used to monitor the temperature of seawater, marine organisms, etc., and find applications in fields such as marine surveying and marine scientific research.Construction Industry: In construction engineering, thermocouples are used to monitor temperature changes in concrete, ensuring the strength and quality of concrete.Nuclear Energy Industry: In nuclear reactors and nuclear power plants, thermocouples are used to monitor the temperature of nuclear fuel and the cooling system of reactors, ensuring the safe operation of nuclear reaction processes.Geothermal Energy Utilization: In geothermal energy utilization systems, thermocouples are used to monitor the temperature of underground water, geothermal wells, etc., to assess the availability of geothermal resources and the operating status of systems.Shipbuilding and Navigation: In shipbuilding, thermocouples are used to monitor the temperature of ship structures and engines, ensuring the safety and performance of ships.

Industrial Automation: Thermocouples are widely used in industrial control systems to monitor and regulate the temperature of various equipment and processes. For instance, they are employed to monitor furnace temperature, melting temperature, and heating system temperature. In the manufacturing industry, thermocouples are utilized to monitor and control temperatures in various production processes such as metalworking, plastic molding, and glass production.Energy Industry: In the production and transmission of energy, thermocouples are commonly used to monitor the temperature of equipment such as boilers, generators, and transmission lines, ensuring the safe operation and quality of products. In the petroleum and natural gas industry, thermocouples are used to monitor the temperature during the extraction, storage, and processing of oil and gas.Automotive Industry: In automobile manufacturing and maintenance, thermocouples are extensively employed to monitor the temperature of engines, transmission systems, exhaust systems, etc., ensuring the normal operation of engines and other critical components. In automotive electronic systems, thermocouples are also used to monitor the heat dissipation of electronic devices, preventing overheating and damage to electronic components.Healthcare: In medical equipment, thermocouples are used in devices such as thermometers and surgical instruments to accurately measure patients' body temperature, aiding healthcare professionals in diagnosis and treatment.Environmental Monitoring: Thermocouples are utilized to monitor temperature changes in the natural environment, such as in weather stations and greenhouses. In environmental protection and pollution monitoring, thermocouples are also widely applied to monitor temperature changes in the atmosphere, water bodies, and other environments.Food Processing and Storage: In the food processing industry, thermocouples are used to monitor temperatures in ovens, refrigeration equipment, etc., ensuring the safe production and storage of food.Aerospace: In the aerospace field, thermocouples are employed to monitor the temperature of aerospace components and devices, ensuring the safe operation of these components in extreme environments.Laboratory Research: In scientific research and laboratory settings, thermocouples are used for temperature monitoring in various experimental equipment and reaction vessels. They find applications in experiments across fields such as chemistry, physics, biology, etc.Chemical Engineering: In chemical production, thermocouples are used to monitor the temperature of equipment such as reaction vessels, distillation towers, and furnaces, ensuring that chemical reactions can proceed under suitable temperature conditions.Metallurgical Industry: In the steel production process, thermocouples are used to monitor temperatures in blast furnaces, smelting furnaces, etc., ensuring the smooth progress of production. In the production of metal alloys, thermocouples are used to monitor the melting point and melting state of alloys, controlling the composition and quality of alloys.Power Industry: In power equipment, thermocouples are used to monitor the temperature of equipment such as transformers, cables, and generators, ensuring the stable operation of power systems.Textile Industry: In textile production, thermocouples are used to monitor temperatures in spinning machines, drying machines, etc., ensuring the quality and production efficiency of fibers.Ocean Engineering: In marine environments, thermocouples are used to monitor the temperature of seawater, marine organisms, etc., and find applications in fields such as marine surveying and marine scientific research.Construction Industry: In construction engineering, thermocouples are used to monitor temperature changes in concrete, ensuring the strength and quality of concrete.Nuclear Energy Industry: In nuclear reactors and nuclear power plants, thermocouples are used to monitor the temperature of nuclear fuel and the cooling system of reactors, ensuring the safe operation of nuclear reaction processes.Geothermal Energy Utilization: In geothermal energy utilization systems, thermocouples are used to monitor the temperature of underground water, geothermal wells, etc., to assess the availability of geothermal resources and the operating status of systems.Shipbuilding and Navigation: In shipbuilding, thermocouples are used to monitor the temperature of ship structures and engines, ensuring the safety and performance of ships.

CHINESE

CHINESE